GBC cutting and beveling tools prepare edges through mechanical material removal without generating a heat-affected zone, ensuring perfect surfaces for industrial-quality welding. They include interchangeable hardened steel blades for reciprocating saws and orbital pipe cutters, solid HSS or carbide-insert tools for split-frame, clamshell, and pipe beveling machines, and milling cutters with interchangeable inserts for plate bevelers. The choice depends on the material being processed, thickness, required bevel geometry, and application type.

What Cutting and Beveling Tools Are

Cutting and beveling tools are cutting elements that remove material from the edges of pipes and plates through cold mechanical cutting and beveling. Unlike thermal methods such as oxy-fuel or plasma cutting, milling keeps the metallurgical properties of the base material intact—an essential aspect for achieving welds compliant with industrial standards.

These tools fall into various categories, including interchangeable blades for reciprocating saws mounted on portable pipe cutters; solid high-speed steel (HSS) tools used in split-frame, clamshell, and pipe-milling machines; and interchangeable carbide inserts mechanically fixed onto rotating cutters or toolholders. This latter solution offers the advantage of quick replacement without regrinding, reducing machine downtime in intensive production environments.

The GBC Industrial Tools range includes solutions for all weld-preparation operations: from straight cutting to facing, external and internal beveling, and tapering, with both standard and custom geometries based on customer specifications.

Materials Used in Cutting Tools

Hardened and Tempered Steel for Blades

GBC reciprocating saw blades use carbon steel subjected to hardening and tempering heat treatment. This process gives the material the hardness required for cutting carbon steel pipes. They can also be coated with TiCN for stainless-steel processing. The alternating toothing ensures clean and precise cuts, with different blade lengths available to suit various diameter ranges.

Cobalt High-Speed Steel (HSS)

Solid tools for pipe bevelers and cutters use cobalt-alloyed high-speed steel with cobalt contents typically ranging from 5% to 10%. According to metallurgical sources, M35 (5% Co) reaches hardness levels of 65–66 HRC with good toughness, while M42 (8% Co) reaches 68–69 HRC with excellent wear resistance.

A key characteristic of HSS is its ability to maintain hardness at elevated temperatures—up to 600°C—thanks to tungsten, molybdenum, and vanadium, which form stable carbides that prevent softening during prolonged high-speed cutting.

Tungsten Carbide

Interchangeable inserts used on pipe beveling machines and plate bevelers are made of tungsten carbide (widia), a composite material produced by sintering tungsten carbide (WC) powder with metallic cobalt. Typical compositions include 80–95% WC with 5–15% cobalt binder.

Superior performance: GBC tungsten carbide features exceptional hardness and maintains cutting-edge integrity at very high temperatures. This thermal resistance allows high cutting speeds, particularly advantageous on hard-to-machine materials such as stainless steel, duplex alloys, and nickel-based superalloys (Inconel).

PVD Coatings

Surface coating significantly increases tool life. PVD (physical vapor deposition) operates at 400–500°C, applying thin layers of titanium carbonitride (TiCN). These coatings reduce friction and chip adhesion, extending tool life by up to 3–4 times.

GBC Industrial Tools applies specific coatings based on the material to be machined: TiCN for stainless steels, and carbide (widia) for particularly tough materials where uncoated tools would be inadequate.

Beveling Tool Geometries

V-Bevel Tools

V-bevels are the most common geometry for preparing butt-weld joints. Standard angles of 30°, 37.5°, and 45° per side—corresponding to total bevel angles of 60°, 75°, and 90°—are widely used for pipes and plates.

On thin wall thicknesses, wider angles are often preferred to facilitate filler metal access, while on thicker sections narrower angles reduce the amount of deposited material while still ensuring full penetration. GBC V-bevel tools are available both as solid HSS versions and with interchangeable carbide inserts.

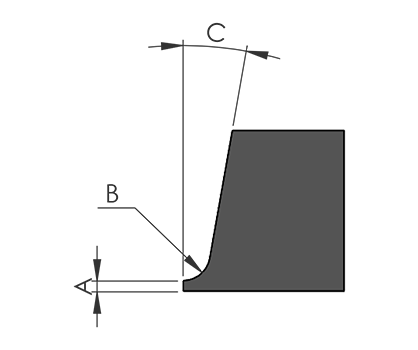

J-Bevel Tools

The J-bevel (J-groove) combines an angled surface with a root radius, creating a profile that resembles the letter J. This type of joint preparation requires a small angle (typically 5°–20°) followed by a radius that facilitates filler metal fusion. The J-bevel is often recommended for thicknesses above 20 mm, where it significantly reduces weld volume compared to a traditional V-bevel.

Producing J-bevels requires tools with specific geometries that combine the angled portion with the curvature radius. GBC pipe bevelers can be equipped with standard tools designed for these complex operations, ensuring dimensional accuracy and repeatability even in series production.

J-bevel

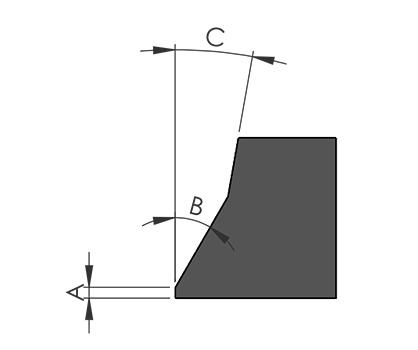

Compound Bevel Tools

The compound bevel (also known as double bevel) features two successive angles on the same edge, typically combining a main angle (30° or 37.5°) with a smaller secondary angle (5° or 10°). This solution is used for very large thicknesses, where it allows filler metal savings of up to 35% while maintaining full weld penetration.

Compound machining requires tools with a complex profile or the sequential use of two tools with different geometries. GBC offers both standard tools for standardized compound geometries and the possibility of developing custom-designed tools for specific applications that require particular angle combinations.

Smusso combinato

Pipe Machining Tools

Blades for Pipe-Cutting Saws

Interchangeable blades on GBC reciprocating pipe saws are made of hardened and tempered steel with optimized toothing for alternate cutting. Each blade fits a specific diameter range—from 1″ to 30″—with different lengths and tooth patterns. Quick blade replacement minimizes downtime.

Tools for Orbital Pipe Cutters

GBC Pipe series orbital cutters (Pipe 4–8) use a sliding-cam engagement system that ensures perpendicular cuts with no burrs. They use dedicated cutting blades; the Pipe 6 can also mount milling cutters for beveling at various angles after cutting.

Tools for Cold Pipe Cutters

Split-frame and clamshell pipe cutters—MCA Cutter, FAST, Supercutter, and Hypercutter—used in oil & gas and pipeline applications include toolholders with external profile-copying systems. This technology compensates for pipe irregularities and ovality, ensuring uniform bevels even on out-of-tolerance pipes. Automatic feed maintains constant machining parameters on pipes from 6″ to 100″.

Standard Tools for Pipe Bevelers

Solid monolithic tools are made from a single piece of cobalt HSS (M35 or M42) or carbide and may include coatings. They are used for external beveling, facing, internal counterboring, and tapering. HSS tools are regrindable and ideal for small-to-medium production runs, while carbide tools offer superior performance on tough materials.

Interchangeable Inserts for Pipe Bevelers

Carbide inserts fixed mechanically onto toolholders allow quick changes in bevel geometry by simply replacing the insert. They are ideal for large-diameter pipes, heavy wall thicknesses, and high-volume production. Compatibility across different GBC beveler models reduces stock requirements.

Plate Beveling Tools

Milling Cutters with Interchangeable Inserts

GBC plate bevelers with insert-based cutters, such as the Manual Edge, Compact Edge, and Edge 80, use mechanically fixed carbide inserts. Worn inserts can be replaced quickly without compromising positioning accuracy. Mechanical clamping ensures superior dimensional repeatability.

Roller Sets for Nibbling Bevelers

The Challenge series nibbling bevelers operate through progressive material removal by shearing. Available angles are: 22°30′, 25°, 30° (supplied as standard), 35°, 37°30′, 45°, and 55°. Roller sets can be replaced in just a few seconds and work on plates from 6 to 40 mm thick, producing uniform edges with bevel widths up to 12–15 mm depending on the model.

Insert Materials for Plate Beveling

Plate beveling inserts are made from tungsten carbide (carbide), a material that provides high hardness and resistance to the abrasive wear typical of machining flat surfaces. Inserts can be supplied with PVD coatings to extend tool life. Insert geometry is optimized to reduce vibration during chip removal, with carefully calibrated rake angles and nose radii to ensure a surface finish suitable for subsequent welding.

Tool Life and Maintenance

The useful life of a tool is defined as the time between two sharpening operations or, in the case of interchangeable inserts, until replacement.

The main wear mechanisms include flank wear caused by friction with the machined surface, crater wear on the tool face due to high-temperature chip flow, and micro-chipping caused by excessive mechanical loads.

Saw blades require sharpening when the cut becomes irregular or greater cutting effort is needed. GBC offers a professional regrinding service performed with the same machines and tolerances used in original production, restoring initial performance at a lower cost compared to purchasing new blades.

Interchangeable inserts eliminate regrinding downtime: when one cutting edge wears out, the insert can be rotated to use a fresh edge or the entire insert can be replaced. This solution is particularly advantageous in continuous production environments where minimizing machine downtime is a priority. The availability of standardized inserts also ensures short procurement times, preventing production delays due to lack of tooling.

Proper lubrication and adherence to the cutting parameters recommended by manufacturers significantly extend tool life.

Excessive cutting speeds generate temperatures that accelerate diffusion wear, while speeds that are too low encourage the formation of built-up edge, compromising surface quality. Periodic monitoring of wear conditions makes it possible to replace tools before they degrade weld-joint quality—an essential aspect for maintaining compliance with industry standards.

Selecting the correct tool involves balancing multiple factors: the workpiece material, the thickness to be machined, the required bevel geometry, and production volumes. GBC Industrial Tools supports customers in this choice through a specialized technical department that develops custom solutions when standard geometries are not sufficient.

The ability to combine pipe bevelers and pipe cutters with plate bevelers allows coverage of the entire range of weld-preparation tasks, from on-site applications to large-scale industrial operations. The regrinding service ensures that even solid tools maintain their original performance cycle after cycle, reducing both environmental and economic impact compared to continuous replacement.

For technical insights or assistance in choosing the right tools, the GBC team is always available at sales@gbcspa.com or through the contact page on the website.