To choose the right beveling machine, it is necessary to evaluate several elements, three of which are fundamental: plate thickness, required bevel type, and production volume. Portable plate bevelers handle thicknesses from 6 to 40 mm for flexible production; automatic machines process up to 80 mm for intensive production; multifunction machines reach up to 120 mm for specialized industries. Cold mechanical milling ensures precision without thermally altering the material.

Why Plate Beveling Is Essential

Properly preparing plate edges before welding is essential to achieve high-quality joints. Correct bevel execution directly affects weld strength, the durability of the finished component, and the overall efficiency of the production cycle.

Beveling creates the optimal angle that allows the filler material to completely fill the joint area. Incorrect edge preparation can cause serious defects such as lack of fusion, insufficient penetration, solid inclusions, and porosity. These issues weaken the mechanical strength of the joint and can lead to premature failures under load.

Among the available technologies, cold mechanical beveling represents the most advanced approach. Unlike heat-based methods such as plasma cutting and oxy-fuel cutting, this process removes material using rotating tools while maintaining ambient temperature, never reaching the melting point. The result is a clean, oxidation-free surface, immediately ready for welding without the need for additional operations.

Types of Plate Beveling Machines

The market offers several categories of beveling machines, each designed for specific production needs. The choice depends on factors such as production volume, thicknesses to be processed, and the required level of automation.

Portable Beveling Machines

Portable beveling machines offer versatility and ease of handling, making them particularly suitable for working on small parts or components with complex shapes. Equipped with milling cutters with replaceable inserts, they allow adjustable bevels at different angles, reaching curved surfaces and hard-to-access areas. Thanks to their light weight and ease of use, they are the optimal choice for light fabrication, aesthetic finishing, and on-site operations where maximum portability is required.

The GBC Challenge range processes plates up to 40 mm thick with fixed angles, while the Manual Edge offers greater versatility thanks to adjustable angles and the ability to follow complex profiles.

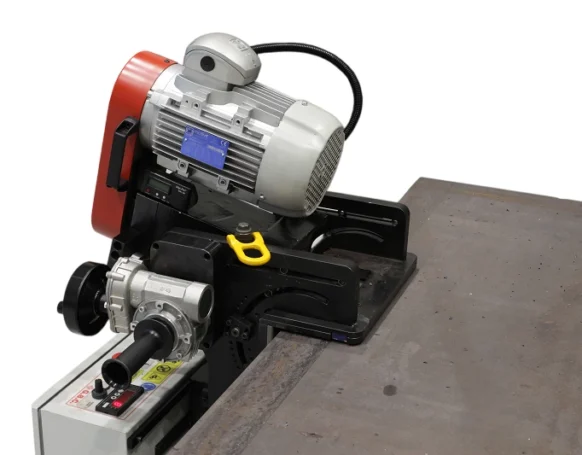

Automatic Beveling Machines with Feed

Automatic plate bevelers are fixed to the edge of the plate and operate independently, minimizing operator intervention. The high-speed rotating head, equipped with carbide inserts, ensures fast processing while maintaining high-quality finishes.

Thanks to integrated shock absorbers, these machines compensate for small surface imperfections, ensuring uniform results even when plates have slight bends or irregularities. Detection devices increase safety during operation by immediately stopping the machine when material is no longer detected.

The GBC Basic Edge 50 processes plates from 6 to 60 mm with a variable angle from 10° to 70°, making it suitable for both intensive production and small workshops. The Compact Edge offers similar performance in a lighter and more manageable structure, while the Edge 80 can handle plates up to 120 mm thick with bevel diagonals up to 80 mm, making it ideal for heavy fabrication.

Multifunction Beveling Machines

Multifunction machines represent the latest evolution of technology, capable of performing multiple types of operations with a single system. In addition to standard beveling, they can perform J-bevels, facing, and cladding preparation, covering virtually all edge preparation requirements.

The cutter speed can be adjusted as needed, typically within a range of 300 to 1500 rpm, allowing settings to be calibrated according to the material type. Through integrated LCD panels, bevel angle and depth can be quickly configured, minimizing downtime when switching between operations.

The GBC Multiedge 80 processes thicknesses from 6 to 120 mm, offering angle settings from 0° to 90° for standard bevels and from 0° to 30° for J-bevels. This operational flexibility is particularly valuable in sectors such as shipbuilding, nuclear, and energy, where welding requirements often change from one project to another.

Not sure which type best suits your production?

Request a free technical consultation to assess your needs.

Key Selection Criteria

Choosing a plate beveling machine requires careful evaluation of production requirements. Three main factors guide the ideal selection.

Thickness and Material Type

Material thickness defines the most suitable machine category. For thin plates from 6 to 40 mm, portable solutions provide the necessary flexibility. Medium thicknesses from 40 to 60 mm require automatic bevelers with feed. For thicknesses over 60 mm, high-power machines such as the Edge 80 or Multiedge 80 are more suitable.

Material type affects insert selection and processing parameters. Carbon steel and stainless steel require different settings: stainless steel needs lower speeds to prevent premature insert wear. Special materials such as duplex steel, Inconel, and high-strength alloys require robust machines with precise feed speed control.

Required Bevel Type

Standard bevels with angles between 15° and 60° represent the majority of applications. They prepare edges for V-groove welds, ideal for medium-thickness plates. Facing is required to remove weld beads or prepare flat surfaces.

When regulations require J-bevels, typical of regulated nuclear and Oil & Gas sectors, multifunction machines capable of producing precise radii are necessary. Cladding preparation is a specialized operation, essential for specific joints or for preparing edges on very thick plates.

Production Volume

A small workshop producing a limited number of parts per day benefits from portable beveling machines as the most economical and flexible solution. The lower cost and ease of use compensate for reduced hourly productivity.

Fabrication shops with medium volumes benefit from automatic bevelers: autonomous feed reduces processing time and ensures uniformity across all batches. Intensive production requires solid, fast, and reliable machines capable of continuous operation with minimal maintenance.

Technical Features to Consider

Angle adjustment must be quick and accurate. Models equipped with digital displays allow precise settings, essential when alternating between different types of operations. Repeatability is a critical requirement: every bevel must strictly meet design tolerances.

Bevel width or diagonal determines machine capacity. Models capable of reaching 80 mm diagonals allow processing of very thick plates with fewer passes. Adjustable feed speed optimizes productivity according to material and thickness.

The machine’s structural robustness ensures stability during processing and long-term durability. High-quality materials and precision manufacturing guarantee consistent performance even under intensive operating conditions.

Ease of insert replacement and spare parts availability significantly affect overall operating costs.

Advantages of Cold Mechanical Milling

Cold milling completely eliminates thermal distortion and the heat-affected zone. During the process, a cutter equipped with carbide inserts removes material from the plate edge while preserving the original mechanical properties of the material.

This technology ensures high dimensional accuracy with tight tolerances, essential for components requiring precise fits. Surface finish reaches excellent levels, often described as “mirror-like,” enhancing filler material adhesion during welding.

This method is particularly suitable for difficult materials such as wear-resistant steels, Duplex, and Inconel. Cold processing preserves the metallurgical characteristics of the base material, which is critical for demanding applications in nuclear, Oil & Gas, and aerospace industries.

Application Sectors

Heavy fabrication processes thick plates intended for load-bearing structures, beams, bases, and large mechanical components. Edge preparation must ensure full-penetration welds capable of withstanding high loads and constant stress.

The shipbuilding, aerospace, and railway sectors are subject to strict regulations regarding weld quality. Plates used for ship hulls, aircraft fuselages, and railway carriages must be prepared according to certified procedures. High-strength steels used in these industries require cold processing to maintain mechanical properties.

The energy and plant engineering industries build pressure vessels, boilers, heat exchangers, and pipelines for hazardous fluids that require welded joints with absolute tightness. In this field, J-bevels are widely used because they reduce the volume of filler material required while maintaining high mechanical strength.

Industrial vehicle manufacturing uses medium-thickness plates for frames and body panels. Beveling prepares edges for final assembly, where productivity and quality must go hand in hand. Tight production cycles require reliable machines capable of ensuring continuous operation.

Investment Evaluation

Choosing the right beveling machine represents a strategic investment for any manufacturing operation. The analysis should consider not only the initial cost but also the return in terms of productivity and quality.

Automatic beveling machines significantly reduce processing times compared to manual operations with grinders. Autonomous feed allows operators to focus on other tasks while the machine completes the beveling cycle. Process repeatability ensures consistent quality across all produced parts.

Operating costs include periodic replacement of carbide inserts, routine maintenance, and energy consumption. High-quality inserts offer longer service life, reducing replacement frequency, while scheduled preventive maintenance extends machine lifespan and prevents costly downtime.

Operator training is a necessary investment to fully exploit machine capabilities. Skilled operators optimize processing parameters according to material, reduce scrap, and maximize productivity. Manufacturer technical support ensures prompt assistance when needed.

Choosing the right plate beveling machine requires a thorough analysis of your production needs. Cold milling technology delivers professional results without compromising material properties, while automation increases productivity and repeatability.

GBC Industrial Tools offers a complete range of beveling machines, from portable models for small workshops to multifunction systems for large plants. In addition to machines, GBC provides continuous technical support, dedicated staff training, and immediate availability of original spare parts.

Contact GBC for a personalized consultation and discover which plate beveling machine can optimize your production processes.