Advantages and challenges of cold working metals: G.B.C. solutions for precise and efficient cutting

Cold working of metals is a fundamental process in modern industry, which involves the transformation of metallic materials without the use of heat, but through direct mechanical applications. Among the main methods of cold working we find the cutting of tubes, a working process that can present various problems.

In addition to precision, the benefits of cold working include increased energy efficiency and reduced operating costs, since there is no need to heat the metals. However, this technique also presents challenges, which are outlined below, and we will also examine three G.B.C. solutions for cold working metals. But let’s start by evaluating the advantages of this particular type of processing.

Advantages of cold metal working

The great advantage is that cold-treated metals do not undergo significant alterations in their structural properties, as happens in hot processes. This allows for precise, high-quality cuts, minimizing the possibility of unwanted distortions or deformations during the process.

Cold cutting is a process that achieves high-precision, high-quality results. This technique requires the use of machinery and tools specifically designed to ensure tight tolerances and minimize material deformation. Particular attention must be paid to the choice of processing parameters, such as cutting speed and proper lubrication, which are essential for preserving the integrity of the tools and ensuring optimal performance over time. Thanks to its reliability and repeatability, cold cutting is particularly suitable for applications requiring high quality and consistent results.

Cold cutting precision: a crucial aspect for professional results

Cold cutting is a technique that requires meticulous management of variables such as speed and depth of cut. Precise control of these variables is essential to avoid overheating and ensure tool life. Too high a speed can damage both the material and the tools, while too low a speed can slow down production, reducing efficiency.

Furthermore, the choice of lubricants is crucial to obtain a high-quality finish. For example, using cutting oil reduces friction, optimizing the process and extending the life of the tools. In general, it is certainly true that the appropriate use of lubricants improves production efficiency and helps reduce operating costs.

Complex metalworking: tackling the challenges of materials like inconel and duplex

Cold working complex metals such as Inconel, duplex and alloy steel presents special challenges. Inconel, for example, is known for its high resistance to high temperatures and corrosion, but it is also a particularly difficult material to machine due to its hardness and tendency to generate a lot of heat during cutting.

To effectively machine these materials, the use of specific tools and careful management of cutting speed are essential. Using specially designed tools helps to extend tool life and minimize the risk of wear. In addition, optimized tool geometry helps to improve cutting accuracy and minimize wear, thus achieving precise and long-lasting results.

Tool maintenance and heat management in the cold cutting process

Another key aspect in cold working is the maintenance of these tools. Well-maintained tools not only ensure a better cut, but also reduce costs in the long run. Regular maintenance reduces the need for frequent replacements and optimizes production costs. Choosing and caring for the right tools is essential to achieve a precise cut and maintain the high quality of the final product.

Heat management is another very important aspect during cold cutting, since overheating can compromise the quality of the cut and the life of the tools. Naturally, thermal control is a parameter closely linked to the cutting speed. The adoption of cooling systems, together with cutting lubricants, helps to dissipate excess heat, avoiding damage to the materials and prolonging the life of the tools.

Cold treatment of special metals: stainless steel and duplex alloy

Cold working special metals, such as stainless steel and duplex alloy, presents unique challenges. Stainless steel, due to its hardness and corrosion resistance, requires constant temperature monitoring to avoid deformation during the cutting process.

The duplex alloy, which combines resistance and anti-corrosion properties, requires particularly careful management of cutting speed and depth. The use of cutting lubricants reduces friction and optimizes cutting even on highly resistant materials, improving the performance of the tools.

Finally, Inconel requires the adoption of highly precise cutting techniques and the use of specialized tools to deal with its hardness and tendency to generate heat during cutting. In these cases, only the adoption of the right technologies is able to guarantee optimal, safe and performing results.

G.B.C. solutions for cold working of metals: innovation and precision

G.B.C. solutions offer cutting-edge technologies for cold metal working, designed to meet the needs of the most demanding industries. Our industrial tube cutters are ideal for tackling the challenges of cutting complex metals, such as overheating, wear and precision.

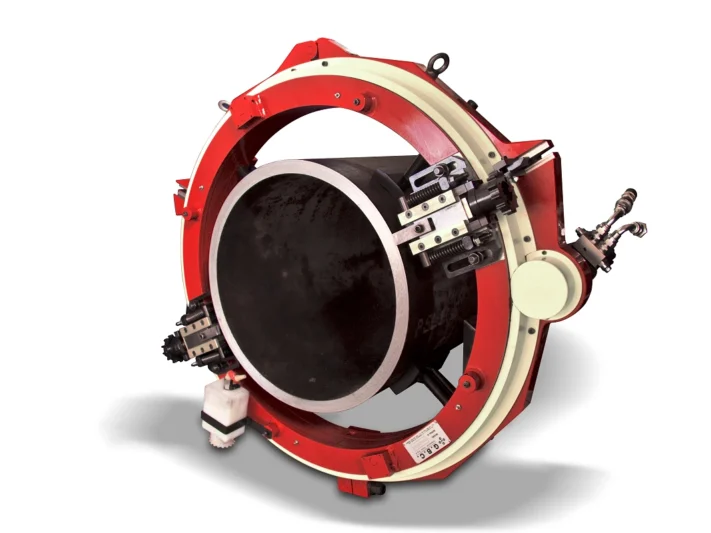

SUPERCUTTER

The Supercutter cold pipe cutter operates on diameters from 168 to 1530 mm (6″–60″). It is ideal for hostile environments such as oil & gas pipelines and offshore platforms. In particular, its innovative bearing system ensures superior execution speed and guarantees both total absence of vibrations and absolute precision in processing. Additionally, the openable machine body allows it to be installed anywhere, and the upper locking jaws have diameter markings for quick positioning. One major advantage is that it has no limits on workable thicknesses, thanks to the customizable tools for every need. Moreover, one of its distinctive features is an oil tank integrated into the ring, which allows the metal to be kept lubricated and cooled during cutting. As for the power supply, this machine offers four options: pneumatic, hydraulic, electric or brushless.

HYPERCUTTER

Hypercutter is an optimal machine for large-diameter pipes. It operates on a range of 1524–2540 mm (60″–100″) and can be used both in the workshop and in the industrial sector. Moreover, it guarantees the perfect chamfering required before welding large pipes. The locking system, in particular, features eight independently adjustable points. As a result, stability during operations is ensured by large contact plates. Furthermore, an advanced copying mechanism on the tool holders compensates for irregularities and ovalizations through automatic feed adjustment. Thanks to its clamshell frame, the machine can be installed at any point along the line and is particularly suitable for handling significant thicknesses, such as those used in the nuclear sector. Finally, this machine is exclusively hydraulically powered.

TAF

The TAF pipe cutter uses an innovative chain locking system. It operates on minimum diameters of 406.4 mm (16″) with no maximum limits. Its design includes two lateral chains and a central guide band, and the guide band guarantees a perfectly linear trajectory with the cut ending exactly at the starting point for impeccable results. Thanks to its features, it is particularly suitable for demolition and tank work, and is also perfect in places where the use of flame involves risks of fire or explosion. Available with a choice of pneumatic or hydraulic motorization (the hydraulic version also performs chamfers on thicknesses of up to 50 mm.)

Optimize your production with G.B.C.

Investing in advanced technologies for cold working metals not only means improving the quality of the final product, but also increasing operational efficiency and reducing long-term costs. G.B.C. solutions are designed to meet the needs of the most demanding industries, offering precise and versatile machines that optimize every phase of the cutting process.

Don’t let issues like overheating or tool wear slow down your production. Contact us today to learn how our innovative solutions can take your cold metal working process to the next level. Choose G.B.C. and transform your production with cutting-edge technology in cold metal working and, in particular, cold pipe cutting.