Metal plate beveling machines are machines that prepare the edges of sheet metal before welding through cold milling, eliminating defects such as lack of fusion and inclusions. Available in portable, automatic, and multifunctional versions, they process sheet metal from 6 to 120 mm thick at variable angles, ensuring precision without thermal distortion of the material.

Metal plate edge preparation is a crucial step in metal fabrication. A properly executed bevel determines the final quality of the weld, the structural integrity of the component, and the efficiency of the entire production process. Modern beveling machines, like those from G.B.C., use cold beveling technologies that guarantee precise results on a variety of materials, from carbon steels to specialty alloys like duplex and Inconel.

Why you should bevel metal plates before welding

Beveling creates the ideal angle to allow the filler metal to fully penetrate the joint. If sheet metal edges are joined without adequate preparation, the risk of defects increases significantly. Improper edge preparation, with a too-closed bevel angle or an excessive landing, can cause lack of fusion and partial penetration.

The beveling process promotes adhesion between the base metal and the filler metal, ensuring optimal conditions for a homogeneous weld. This results in stronger, more durable joints that comply with the high safety standards required in the most demanding industrial sectors.

What problems does beveling solve?

The most common defects caused by inaccurate bevels include:

- Lack of fusion during welding

- Insufficient penetration

- Solid inclusions

- Blowholes

Lack of fusion occurs when the filler steel does not fully bond with the base steel, creating discontinuities in the joint. Partial penetration leaves part of the root unwelded, significantly reducing the load-bearing capacity of the structure.

Slag inclusions form when the edge preparation is inadequate or the slag from the previous pass is not properly removed. These defects weaken the mechanical strength of the joint and can cause premature failure under load. Accurate beveling eliminates these problems at the source, ensuring welds of certifiable quality.

Beveling technologies: cold beveling

Cold beveling is the most advanced solution for metal plate beveling. Unlike thermal processes, this technology removes material using rotating tools, without melting the metal. Its main advantage is the complete absence of thermal deformation and a heat-affected zone (HAZ).

During the process, a cutter equipped with carbide inserts removes material from the edge of the sheet metal, forming the desired angle. The process occurs at room temperature, maintaining the material’s original mechanical properties. The result is a clean, oxidation-free surface that is immediately ready for welding, without the need for further processing.

Cold beveling ensures high dimensional accuracy with tight tolerances, essential for components requiring precise fits. The surface finish achieves excellent levels, often described as “mirror-like”, promoting the adhesion of the filler metal during welding. This technology is particularly suitable for difficult materials such as wear-resistant steels, Duplex, and Inconel.

Types of Metal Plate Beveling Machines

The market offers various categories of beveling machines, each designed for specific production needs. The choice depends on the production volume, the thicknesses to be processed, and the degree of automation required.

Portable bevelling machines

Portable machines are compact and versatile solutions, ideal for machining small or complex workpieces. Equipped with interchangeable insert cutters, they allow for chamfering with variable angles, even on curved or difficult-to-access surfaces. Their low weight and ease of use make them perfect for light carpentry, aesthetic beveling, and on-site operations where mobility is essential.

GBC’s Challenge range processes sheet metal up to 40 mm thick with fixed angles, while the Manual Edge offers greater versatility thanks to adjustable angles and the ability to follow complex profiles.

Challenge Plate beveling machine by GBC

Beveling machines with automatic feed

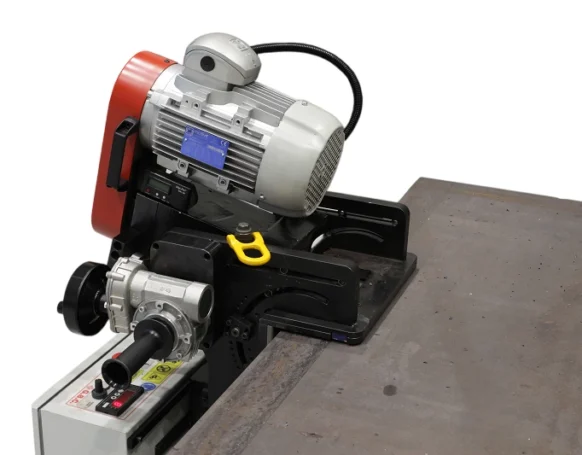

The automatic plate beveling machines, equipped with automatic feed systems, attach to the edge of the sheet metal and operate independently, minimizing operator intervention. The high-speed rotating head, equipped with carbide inserts, ensures rapid processing while maintaining a high-quality finish.

The shock-absorbing system compensates for any surface irregularities, ensuring uniform processing even on slightly curved or imperfectly flat sheets. Sheet metal detection sensors improve operational safety by automatically stopping the machine if material runs out.

GBC’s Basic Edge 50 processes sheet metal from 6 to 60 mm with a variable angle from 10° to 70°, making it suitable for both intensive production and small workshops. The Compact Edge offers similar performance in a lighter, more maneuverable design, while the Edge 80 can handle sheet metal up to 120 mm thick with bevel angles of up to 80 mm, making it ideal for heavy-duty carpentry.

Multifunctional beveling machines

Multifunctional machines represent the latest evolution in technology, capable of performing different types of processing with a single system. In addition to standard beveling, these beveling machines produce:

- J-bevels (for example with radii R6 and R8)

- Landing

- Flaking

Covering virtually all edge preparation needs.

The cutter speed is adjustable, typically from 300 to 1500 rpm, allowing optimization of parameters based on the material being processed. Integrated LCD displays allow quick angle and depth settings, reducing setup times between different operations.

The Multiedge 80 from GBC handles sheet metal from 6 to 120 mm thick, with adjustable bevel angles from 0° to 90° and J-bevels from 0° to 30°. Its versatility makes it indispensable in the naval, nuclear, and energy sectors, where welding specifications vary frequently. Read the dedicated article about the Multiedge 80

Plate beveler Multiedge 80 by GBC

How to choose the right beveling machine

Choosing a sheet metal beveling machine requires a careful assessment of production needs. Three main factors guide the ideal selection: material properties, the desired bevel type, and the expected production volume.

Sheet metal thickness and material

Material thickness determines the most suitable machine category:

- Thin sheet metal (6-40 mm): portable solutions provide the necessary flexibility

- Medium thicknesses (40-60 mm): require automatic plate beveling machines with feed

- Thicknesses greater than 60 mm: high-powered machines such as the Edge 80 or Multiedge 80 are essential

The type of material affects the choice of inserts and machining parameters. Carbon steel and stainless steel require different settings: stainless steel requires lower speeds to avoid premature insert wear. Specialty materials, such as duplex, Inconel, and high-strength alloys, require robust machines with precise feed speed adjustment.

Required angle and type of bevel

In addition to landing, standard bevels with angles between 15° and 60° constitute the majority of applications. They prepare the edges for V-bevels, ideal for medium-thickness sheet metal. When regulations require J-bevels, typical of the nuclear and oilfield industries, multifunctional machines capable of producing highly precise radii are required. Flaking is a specialized process, essential for special joints or for preparing edges on thick sheet metal.

Angle adjustment must be quick and accurate. Models equipped with a digital display allow for precise settings, which is essential when alternating between different types of machining. Repeatability is a key requirement: each bevel must strictly adhere to design tolerances to ensure perfectly compliant welds.

Production volume

A small company producing a few parts per day finds portable beveling machines the most economical and flexible solution. Their low cost and ease of use offset the lower hourly productivity. Medium-volume fabrication shops benefit from automatic beveling machines: the independent feed reduces processing times and ensures consistency across all batches.

Intensive production requires robust, fast, and reliable machines. High-end automatic beveling machines operate continuously with minimal maintenance. The ability to invert the machine to also bevel the underside of the sheet metal, available on Reverse models, doubles efficiency when processing both sides.

Industrial applications of metal plate beveling

Various industrial sectors require professional beveling to ensure the quality and safety of welded structures.

Heavy metal carpentry

Heavy carpentry works with thick sheet metal intended for load-bearing structures, beams, bases, and large mechanical components. Edge preparation must ensure full penetration welds capable of withstanding heavy loads and constant stresses. Bevels must meet strict tolerances to ensure uniform stress distribution within the structure.

Plates thicker than 60 mm require deep bevels, with optimized angles to allow the welder to completely fill the joint with multiple passes. The quality of the preparation directly affects the number of passes required and, consequently, the overall welding costs.

Naval, aeronautical, railway sectors

These sectors are subject to stringent regulations regarding welding quality. Sheet metal intended for ship hulls, aircraft fuselages, and railway carriages must be prepared according to certified procedures and accompanied by complete process documentation. The high-strength steels used in these fields require cold working, which is essential to maintain the mechanical properties of the base material.

The components can be very large: 10 to 20 meter-long panels, typical of the naval sector, require highly reliable automatic feed beveling machines. The finish must be impeccable to avoid any potential for cracking or corrosion.

Energy and plant industry

The construction of pressure vessels, boilers, heat exchangers, and pipelines for hazardous fluids requires welded joints with absolute leak-tightness. In this field, J-bevels are widely used because they reduce the volume of filler metal required while maintaining high mechanical strength.

Standards such as ASME, EN 13445, and API 650 precisely define the geometries and tolerances of bevels. Documentation of the preparation process is an integral part of component qualification. The beveling machines used must guarantee complete repeatability and traceability of processing parameters.

Industrial Vehicle Construction

Trucks, trailers, earthmoving equipment, and specialty vehicles use medium-thickness sheet metal for frames and body panels. Chamfering prepares the edges for final assembly, where productivity and quality must go hand in hand. Tight production cycles require reliable machinery capable of ensuring operational continuity with minimal downtime.

Edge finishing removes burrs and sharp edges, increasing operator safety during assembly and reducing the risk of paint damage during subsequent surface treatments.

Choosing the right beveling machine is a strategic investment for any sheet metal manufacturing company. Cold beveling technology guarantees professional results without compromising the material’s properties, while automation increases productivity and repeatability.

GBC offers a full range of solutions for every need, from light carpentry to the most complex industrial systems. Contact us for a personalized consultation and discover which sheet metal beveling machine can optimize your production processes.