In the world of industrial maintenance, flanges are a critical point, which is why GBC has developed a flange facing system with assisted machining. A damaged surface can compromise the sealing of an entire system. For this very reason, the Spider 12_70 was created to solve this problem with surgical precision.

This machine handles flanges from 12 to 70 inches. This is an impressive range that, consequently, covers many modern industrial needs. Furthermore, flange facing with assisted machining via on-board software completely transforms the traditional approach.

In practice, simply enter the machining parameters into the integrated computer. The machine then automatically calculates the initial setup position and then manages the entire cycle. Therefore, no more manual calculations and, above all, no more wasted precious time.

The technical features that make the difference

First and foremost, the Spider 12_70 offers a tool holder radial travel of 272 mm. This means it can work on large surfaces without constant repositioning. Furthermore, the 60 mm vertical travel also allows for the management of flanges with complex geometries.

The self-centering clamping system completely eliminates positioning errors. Therefore, once the flange is secured, precision is guaranteed throughout the entire process. Likewise, the variable feed rate from 0 to 1.2 mm per revolution allows for different finishes as needed.

The pneumatic version delivers 3.1 kW of power. Furthermore, spindle torque reaches 1015 Nm, sufficient for machining tough materials. Air consumption of 2800 Nl/min requires a suitable compressor, though this is still standard.

The hydraulic version, however, pushes performance even further. Indeed, with 3.8 kW of power and 1400 Nm of torque, it tackles even the toughest steels. Furthermore, the oil flow rate of 30 liters per minute maintains optimal operating temperatures throughout the process. In short, given all this, it’s easy to understand why the Spider 12_70 is one of our best machines for industrial flange maintenance.

Operational versatility: two facing modes

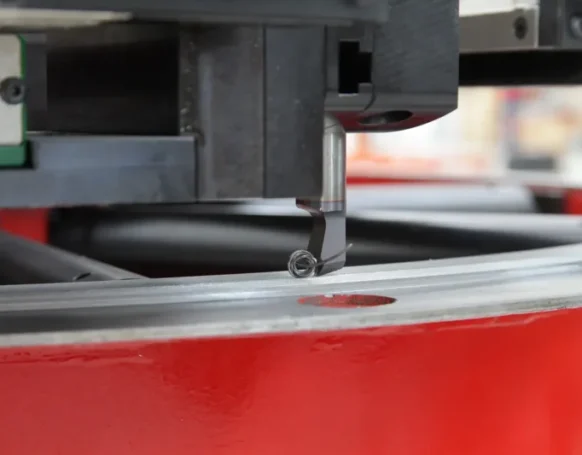

First, the standard configuration uses high-speed (HSS) tools for flange facing with a controlled machining system. This solution guarantees excellent results on most materials. In particular, cylindrical tools allow for precise and, above all, repeatable machining.

However, when greater aggressiveness is required, the optional insert cutter comes into play. With its support arm and a dedicated 2.2 kW motor at 750 rpm, it can remove material rapidly.

The cutter’s dedicated pump delivers 120 bar of pressure. This ensures smooth and controlled movements even under heavy loads. At the same time, the flow rate of 25 liters per minute ensures immediate response to controls.

Carbon steels, stainless steels, duplex, and even Inconel are no problem. In fact, the Spider 12_70 automatically adapts the working parameters to the selected material as the software calculates the optimal speeds and feeds for each specific situation.

The on-board software: the brain of the machine

First of all, forget about machining tables and complex manual calculations. The Spider 12_70’s integrated computer manages everything through an intuitive interface. Simply enter the flange diameter, the type of fluting, and finally the desired finish.

The flange facing system with assisted machining automatically calculates the optimal starting point for the tool. It then determines the number of passes required and the depth of each pass. Finally, it even optimizes the rotation speed based on the actual working diameter.

During machining, the software constantly monitors operating parameters. If it detects anomalies, it automatically adjusts the parameters to maintain quality. This self-adjusting ability drastically reduces scrap and rework.

Another important advantage: program storage allows you to quickly recall frequent machining operations. For example, do you have a series of identical flanges that you periodically machine? If so, save the program and recall it when needed. As a result, you’ll save valuable time with every job.

Practical applications in the real world

First and foremost, the hydraulic industry is one of the main application sectors. Flanges in fluid transport systems require perfect grooves to ensure a tight seal. Therefore, the Spider 12_70 restores phonographic or spiral grooves with micrometric precision.

Similarly, in the food and pharmaceutical industries, surface quality is crucial. Grooves must meet rigorous hygiene standards to prevent contamination. Therefore, software control ensures finishes compliant with the most stringent regulations through flange facing with an assisted machining system.

Medical gas systems require perfect seals for safety reasons, as a leak could have serious consequences in a hospital environment. This is why the Spider 12_70 ensures flawless sealing surfaces for critical applications.

Furthermore, this machine also makes routine maintenance more efficient. Instead of replacing slightly damaged flanges, you can repair them on site. Consequently, the cost and time savings are evident from the first intervention.

The investment that pays off: value analysis

First, let’s consider the hidden costs of damaged flanges that aren’t properly repaired. These include product losses, unplanned downtime, and environmental and safety risks. Indeed, a single major leak can cost thousands of euros in just a few hours.

However, the Spider 12_70 eliminates these risks through precise and repeatable machining. Furthermore, flange facing with an assisted machining system also reduces the dependence on highly specialized operators. Therefore, even technicians with average experience can achieve professional results thanks to our integrated software.

An additional advantage: the option of choosing between pneumatic or hydraulic power increases flexibility. In other words, you can integrate the machine into your existing infrastructure without additional investments. If you already have an efficient pneumatic system, you can directly leverage your existing one.

Furthermore, customization to meet specific customer needs represents a fundamental added value. G.B.C. adapts each machine to your specific operational needs. Therefore, there is no compromise between standard functionality and your specific production requirements.

Ultimately, investing in a Spider 12_70 means investing in future operational peace of mind. Reliability, productivity, and long-term economic benefits are guaranteed. Furthermore, flange facing with an assisted machining system represents the technological evolution that every modern company should consider to remain competitive.

So, don’t wait for a damaged flange to cause a costly downtime. Contact G.B.C. now at (+39) 030 745.11.54 or, alternatively, email sales@gbcspa.com. Our team of experts responds immediately to customer emergencies.

Finally, our specialized technical consultancy will guide you in choosing the optimal configuration. Support continues even after purchase with dedicated technical assistance. Because, after all, G.B.C. It doesn’t just sell machines: it builds lasting partnerships for your success.