Cutting pipes of different diameters requires versatile solutions capable of covering wide ranges without compromising precision. The main challenges include frequent tool changes, operator training, and adaptability to challenging conditions while ensuring consistent quality.

GBC Industrial Tools has developed a complete range of pipe cutting and beveling machines capable of covering a wide spectrum of industrial needs, from 1″ to 100″ in diameter. This versatility, combined with guaranteed precision on all materials, makes GBC solutions a benchmark for industry professionals.

In this article, we will explore how to effectively address the challenges of multi-diameter cutting, analyzing the different technologies available and the resulting operational advantages.

Why is cutting pipes of different diameters a challenge?

Every industry has specific requirements for pipe diameters. Even within the same industry, different projects often require different diameters and therefore versatile equipment, impacting investments, space requirements, and operational management.

The first challenge is covering the required operating range. Many pipe cutting machines on the market handle limited ranges. Even when a company primarily operates within a defined range, acquiring new orders or expanding into different projects may require capabilities for additional diameters. This means choosing between limited business opportunities and investing in additional equipment, with consequent impacts on costs, workshop space, and tool inventory management.

A second challenge is the need to maintain consistent precision. Accurately cutting 1-inch pipes is technically different from machining 100-inch diameter pipes. Pipe wall thicknesses vary, materials range from mild steel to high-strength alloys, and each combination requires specific cutting parameters. Maintaining the same cutting and beveling quality across the entire range is therefore not a given.

How wide is the diameter range in industrial applications?

Actual market needs vary greatly depending on the industry. In some industrial sectors, the most commonly used pipes are those with diameters between 1 and 12 inches. In others, diameters range from 20 to 48 inches and beyond, even reaching 100 inches for specific applications.

This variety creates challenges for both specialized workshops and in-house technical departments, which often find themselves forced to equip themselves to cover a wide range of diameters. Flexibility is therefore required: the ability to quickly switch from one diameter range to another without production downtime or continuous investment in completely new equipment.

The problem of continuous machine changeovers

When the operating range of individual machines is limited, companies working with pipes of different diameters are forced to purchase different equipment. This can create a series of complications: each machine often requires specific tools, operates according to its own operating parameters, and is uniquely suited to its use.

Furthermore, operators must familiarize themselves with different machines, resulting in longer training times and a greater risk of errors when switching from one tool to another. The inventory of spare tools increases, as do maintenance costs. And every time the diameter range expands, a significant investment in a new machine is required.

The solution? Rely on a single supplier that offers a complete range for a wide range of diameters.

GBC solutions for pipe cutting

GBC pipe cutting machines cover diameters from 1 to 100 inches and, in many cases, use the same accessories and operating logic. Thus, by purchasing multiple models for different diameters, the company saves on both accessories and staff training. This approach solves the problem of constant machine changeovers while maintaining operational consistency.

Let’s take a practical example. A series of machines, such as the MCA Cutter, can cover a total of 1 to 43 inches, but this range is divided into specific ranges: one handles 1 to 3 inches, another 2 to 6 inches, yet another 3 to 8 inches, etc.

Buying two models with different ranges doesn’t mean changing the machine type but simply switching to the next model in the same family. This way, operators already know the operating logic, the tools are often compatible, and no additional training is required.

GBC applies this principle across its entire range: the MCA series covers 1 to 43 inches, while the Supercutter and Hypercutter also handle larger diameters, up to 60 and 100 inches. The result is complete coverage from 1 to 100 inches with continuous operation. Discover all GBC pipe cutting solutions.

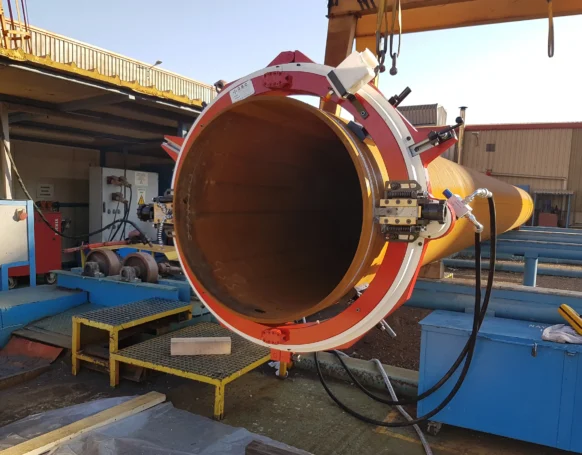

GBC Supercutter Pipe Cutting Machine in action

Reduced training, shared accessories and tools

When the machine type remains the same and only the operating range changes, the benefits are tangible. The interface, controls, and operating procedures remain familiar, allowing for immediate production start-up with no learning curve.

Furthermore, spare parts inventory is simplified, management costs are reduced, making in-house maintenance more efficient, and allowing technicians with existing knowledge of the mechanics to intervene quickly.

Does precision remain consistent across all diameters and materials?

A versatile machine is useless if cutting quality varies depending on the diameter or material. Consistent precision must be guaranteed, as the cut components will later be welded, and an incorrectly executed chamfer can compromise the mechanical strength of the joint.

A correct chamfer (or bevel) must be uniform and consistent across the entire diameter and wall thickness of the pipe, without burrs or irregularities. When this is done optimally, weld penetration is optimal and the joint achieves maximum strength.

Difficult materials and thicknesses

High-strength steels used in critical applications require machines capable of maintaining precision even under high stress. Wall thicknesses on large-diameter pipes can often exceed 50 mm, and cutting this material without deflection or vibration requires adequate structural rigidity and power.

Professional pipe cutters ensure consistent quality regardless of the material being processed: carbon steel, stainless steel, Inconel, duplex, or even others. This consistency is crucial in industries where quality standards are stringent and allow for no defects.

GBC solutions guarantee precision on all diameters (from 1 to 100 inches), on all wall thicknesses, and on any type of material, including the toughest steels used in the most demanding applications.

Is there a one-size-fits-all solution?

There’s no perfect machine for every situation, but there is the right approach: having access to different construction types while maintaining consistency in the operating logic. Those working with variable diameter ranges need flexibility without fragmenting their machine fleet into completely different equipment.

GBC offers a complete range of both operating ranges (from 1 to 100 inches) and construction types (split frame, clam shell, chain system). This means you can choose the specific machine for each application, maintaining continuity as the range of workable diameters expands.

About us:

GBC Industrial Tools is a leading manufacturer of pipe cutting and beveling machines, with a complete range of solutions covering diameters from 1″ to 100″. The company stands out for its variety of machine types (split frame, clam shell, self-centering) and its ability to work with different materials and thicknesses. Contact us now for a personalized professional consultation.