Metal welding and environmental impact: strategies for reduced impact

In today’s industrial landscape, sustainability in metalworking has become a top priority. Environmental impact and metal welding, which is one of the most energy-intensive processes, are therefore directly linked issues. In particular, the use of inefficient technologies and non-renewable energy sources for welding metals or other materials generates high greenhouse gas emissions and air pollution. The need to reduce these emissions and improve energy efficiency is therefore increasingly urgent.

An important strategy for improving sustainability in the metal welding industry is to adopt advanced technologies that reduce energy consumption. For example, more efficient welding processes that use renewable energy sources such as solar and wind are key to reducing carbon emissions. These technologies enable greener metalworking while reducing operating costs for companies. These solutions are crucial not only for the health of the planet, but also for improving the competitiveness and profitability of companies in the long term.

The role of metal recycling in welding sustainability

Metal recycling is one of the most effective practices to reduce the environmental impact of metal processing, including welding. In particular, recycling metals such as aluminum, copper and steel allows to drastically reduce energy consumption compared to the production of virgin metals. This process is also advantageous from an economic point of view, as recycled metals are cheaper than new ones, reducing production costs and improving competitiveness on the global market.

Additionally, the use of recycled metals in welding enables traceability of the materials used, facilitating compliance with environmental regulations and certification of production processes. This is particularly relevant in regulated sectors such as aerospace, automotive and public construction, where the provenance of materials and their sustainability may be a key requirement. Traceability, combined with the consistent quality of modern recycled metals, helps ensure reliability and safety in the most critical applications.

Advanced welding technologies for more sustainable manufacturing

Advanced technologies in metal welding are evolving rapidly, contributing significantly to the sustainability of the sector. For example, a frontier of sustainable innovation in welding is represented by the integration of digital systems and intelligent sensors in manufacturing processes.

The use of real-time monitoring technologies allows to instantly detect and correct any misalignments or thermal anomalies, avoiding material waste and improving process repeatability. Furthermore, the analysis of data collected during welding operations allows companies to optimize technical parameters and minimize rework, with a direct impact on the reduction of energy consumed.

The introduction of energy-efficient welding techniques reduces not only consumption but also harmful emissions. Low-emission welding processes, combined with the use of innovative couplers, such as the Gold Bridge Clamps designed and manufactured by G.B.C., can further improve precision and reduce energy waste. The adoption of these technologies not only optimizes the use of resources but also allows for precise alignment of metals during the welding process, ensuring a superior quality of the final product.

Welding clamps: precision and process safety

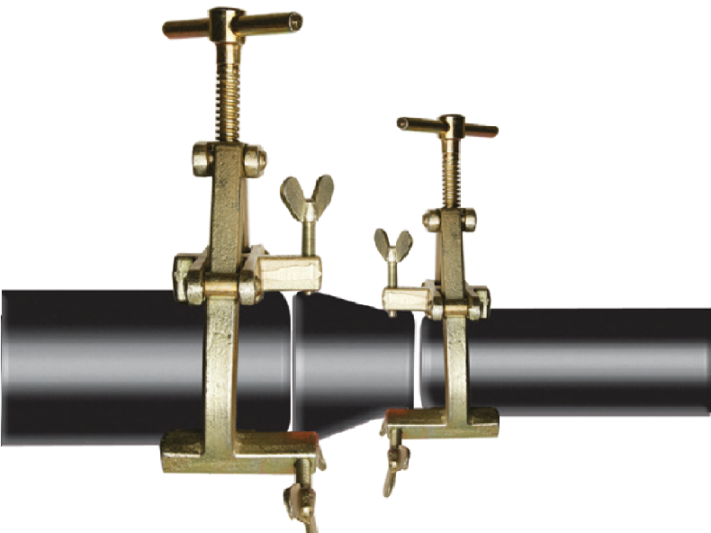

Welding clamps are essential tools for more precise and safe metalworking. These devices help keep metal components aligned during welding, preventing defects and improving the overall quality of the process. In particular, G.B.C. Gold Bridge Clamps are known for their robustness and reliability, making them ideal for a variety of industrial applications, including welding in the oil and gas and construction industries. With these tools, companies can achieve greater operational efficiency and reduce the risk of errors that could compromise the final quality of the product.

Metal welding with Gold Bridge Clamps: economical and reliable solution for pipe centering

Gold Bridge Clamps are one of the most reliable and economical solutions for centering pipes in welding projects. These clamps, made of heavy-duty forged steel, offer extraordinary strength and durability, ensuring precise and safe alignment. Due to their solid construction, Gold Bridge Clamps are ideal for welding operations in a variety of industries, such as oil and gas, construction and maintenance. Their ease of use and operational efficiency make them an excellent option for a wide range of industrial applications.

Using Gold Bridge Clamps allows for precise and efficient tube alignment, improving the quality of work and reducing intervention times. This makes Gold Bridge Clamps an ideal choice for projects where precision is essential. Furthermore, the adoption of these clamps helps to increase operational safety, reducing the risk of unwanted tube movements during the welding process.

For extra protection, an optional stainless steel cover kit is available. This easy-to-fit accessory makes the clamp contact points rustproof, preventing corrosion and further improving the life of the clamps, maintaining the quality of the welding project..

| Models Available |

GBC3, GBC5, GBC7, GBC9, GBC14 |

| Diameter Range (O/D) |

25,4 – 355,6 mm (1” – 14”) |

| Material |

Forged steel, ensuring strength and durability |

| Usage |

Easy and quick to use, ideal for welding applications |

| Performance |

High precision and safety in tube centering |

| Bolts |

Stainless Steel Bearing Wing Bolts |

| Weight |

GBC3: 1,4 kg – GBC5: 3 kg – GBC7: 3,3 kg – GBC9: 7 kg – GBC14: 7 kg |

| Dimensions (mm) |

GBC3: 20-90 mm, GBC5: 50-150 mm, GBC7: 90-190 mm, GBC9: 125-225 mm, GBC14: 225-370 mm |

| Applications |

Oil & Gas, Construction, Maintenance |

| Optional Accessories |

Stainless steel cover kit for corrosion protection |

| Important Notes |

Do not use as a lifting device; independent support required |

| Advantages |

Economical and reliable, it improves efficiency and reduces working times |

Towards a more sustainable future in metal welding

The metalworking industry is rapidly evolving towards more sustainable practices, responding to the growing demand for high-performance, environmentally friendly solutions. By adopting advanced technologies, such as metal recycling and the use of renewable energy, the industry is reducing its environmental impact and improving energy efficiency. These advances not only address environmental needs, but also provide tangible economic benefits for companies, such as reduced operating costs and improved competitiveness.

Tools such as couplers and centering clamps, such as Gold Bridge Clamps, play a crucial role in improving accuracy and safety during welding. The adoption of these tools indirectly contributes to sustainability, optimizing resources and reducing energy waste. Operational efficiency increases and the final quality of welding projects benefits, ensuring long-lasting and reliable results.

Looking ahead, it is clear that the transition to greener and more technologically advanced practices is inevitable. Companies that embrace these innovations will not only help protect the environment, but will also be better positioned to address the challenges of the increasingly sustainability-conscious global market.

Take action today for a more sustainable tomorrow: choose Gold Bridge Clamps by G.B.C.

If your company aims to combine efficiency, sustainability and quality in metal welding, it is time to take a concrete step towards innovation. Gold Bridge Clamps by G.B.C. represent a strategic solution for those who want to improve their production processes without compromise: maximum precision in tube centering, increased operational safety and a significant reduction in intervention times..

Designed to withstand even the most demanding conditions, Gold Bridge Clamps ensure perfect alignment thanks to their forged steel construction and high-quality components. With models available for a wide range of diameters and application sectors – from the oil industry to construction – these clamps are perfectly suited to every professional welding need..

Investing today in tools like Gold Bridge Clamps means optimizing resources, improving the quality of work and actively contributing to environmental sustainability. Contact us to receive more information or personalized advice. The future of welding passes through G.B.C.