Description

Plate beveling machine EDGE 80

Range w.t. 6-120 mm (1/4” – 4 ¾”)

The plate beveling machine EDGE 80 is a high-speed plate beveling machine with high beveling capacity. It is fast and precise, thanks to the face mill equipped with high speed interchangeable inserts.

The EDGE 80 can work on plates from 6 to 120 mm of thickness, can reach a maximum diagonal of 80 mm and it is equipped with a stepless variable head type which allows bevel angles from 10° to 70°, granting a very easy and quick adjustment of the angle of bevel. This machine can also perform J Bevel (R6 and R8) from 0° to 30°.

The plate beveling machine EDGE 80 is equipped with a plate detecting sensor and trolley with a new chips conveyance system. It is also equipped with amortization system which allows to overcome eventual imperfections of the plate or of the ground.

The EDGE 80 can bevel any material with smooth surface finishing, groove free. Once the machine is placed and secured on the plate it runs along the edge up to the far end with no intervention by the operator.

MACHINE FEATURES

RANGE:

6-120 mm thickness (1/4” to 4 ¾”).

FUNCTIONS:

Bevel from 10° to 70°.

J Bevel (R6 and R8) from 0° to 30°.

MATERIALS:

Carbon steel, stainless steel, duplex, super duplex, inconel, aluminium, etc.

POWER:

Electric 3 phase 400V 50Hz.

OPTIONAL:

Speed Regulator.

EDGE 80 – Pictures

The EDGE 80 series metal bevellers are designed to perform J-bevels of various angles and radiuses (see table in the technical data sheet). Such a result

can be obtained simply by replacing the cutter supplied with a cutter with round inserts, with variable geometries based on the customer’s needs.

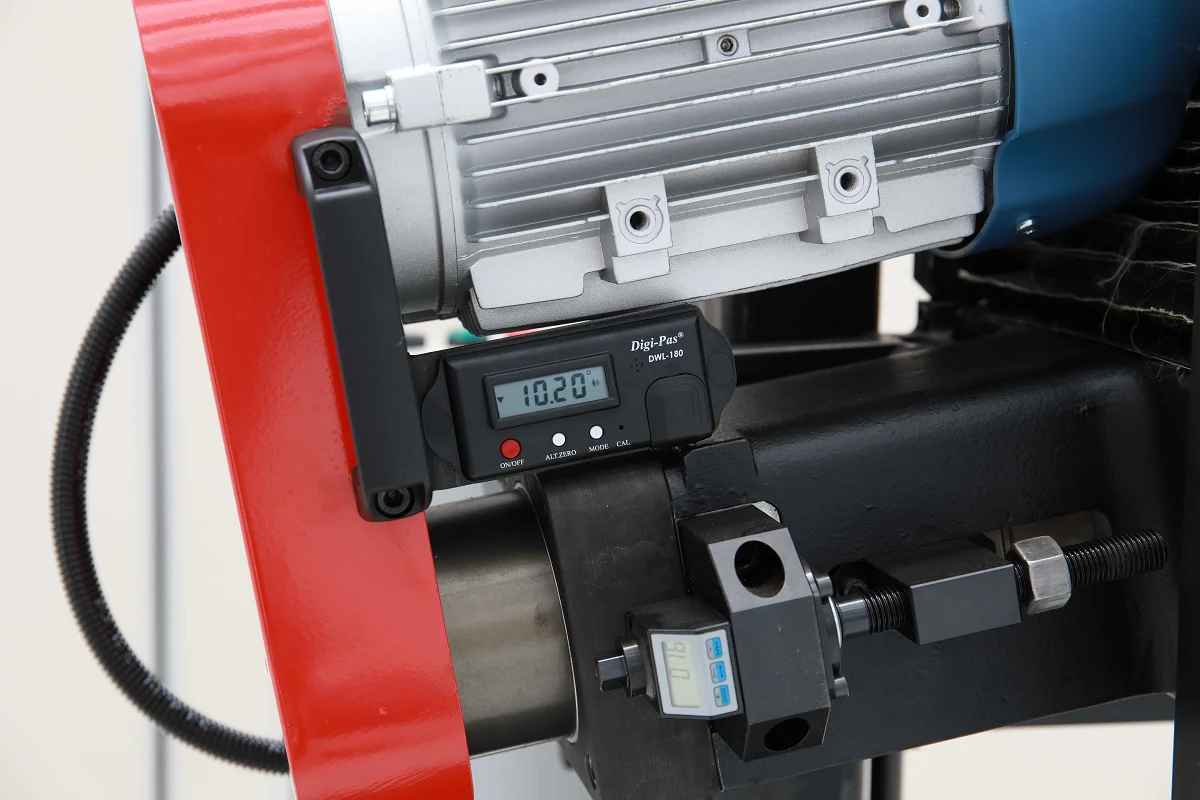

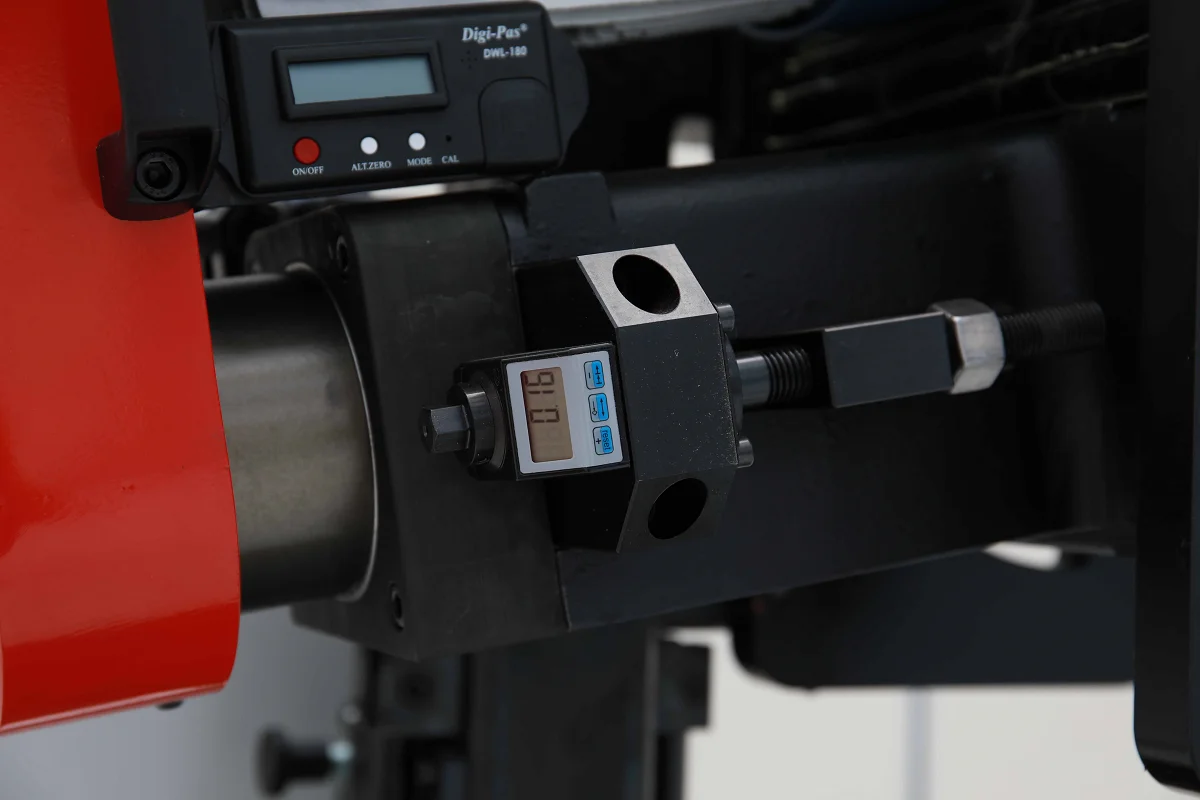

The phases of setting the bevel angle and the depth of the pass are particularly simple and fast thanks to the presence of two LCD displays.

With the optional cutter speed regulator, the rpm. of the mill can be reduced for an optimal result on all types of materials.

Contact us if you are interested in the Edge 80 or would like to receive a free quote.