Description

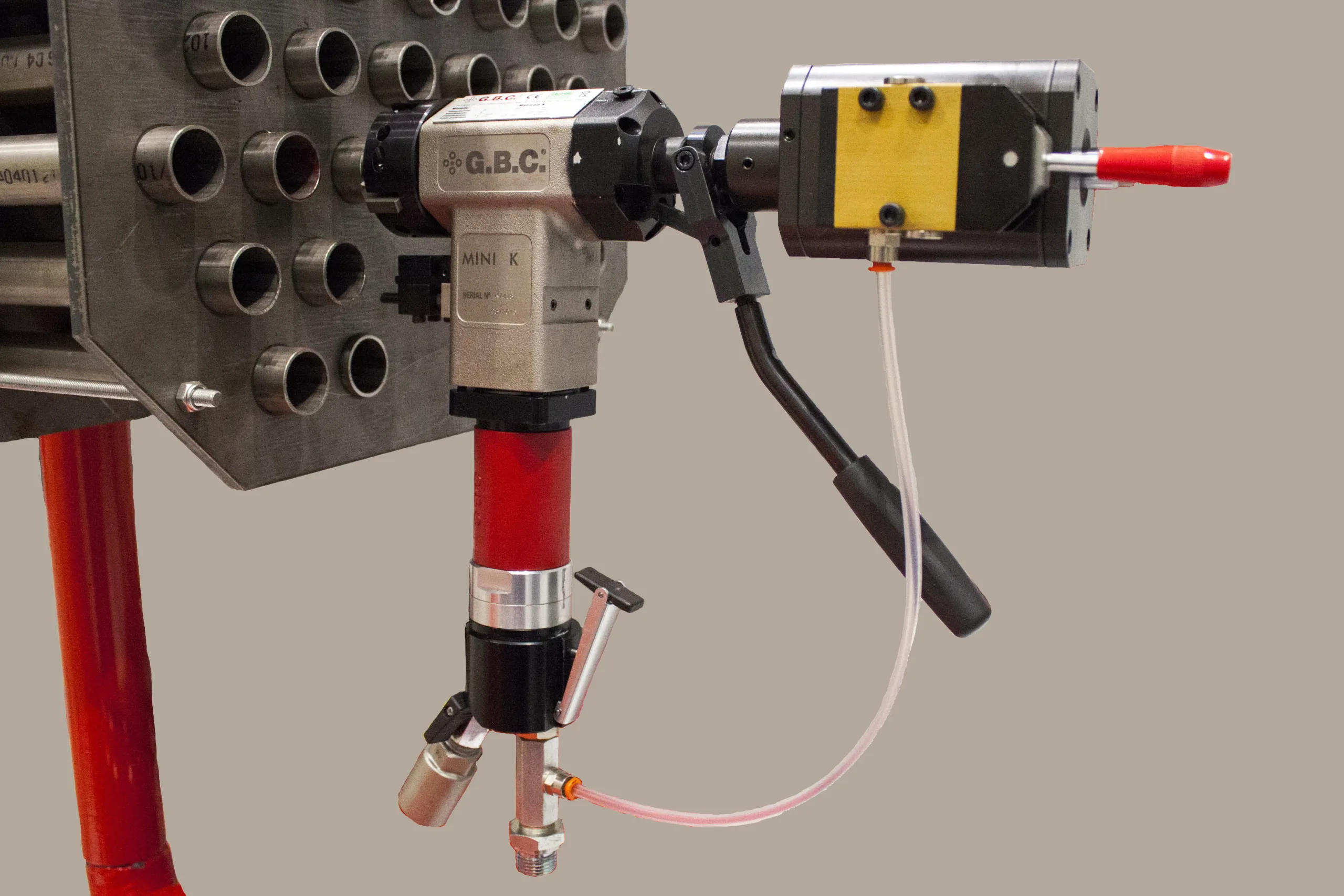

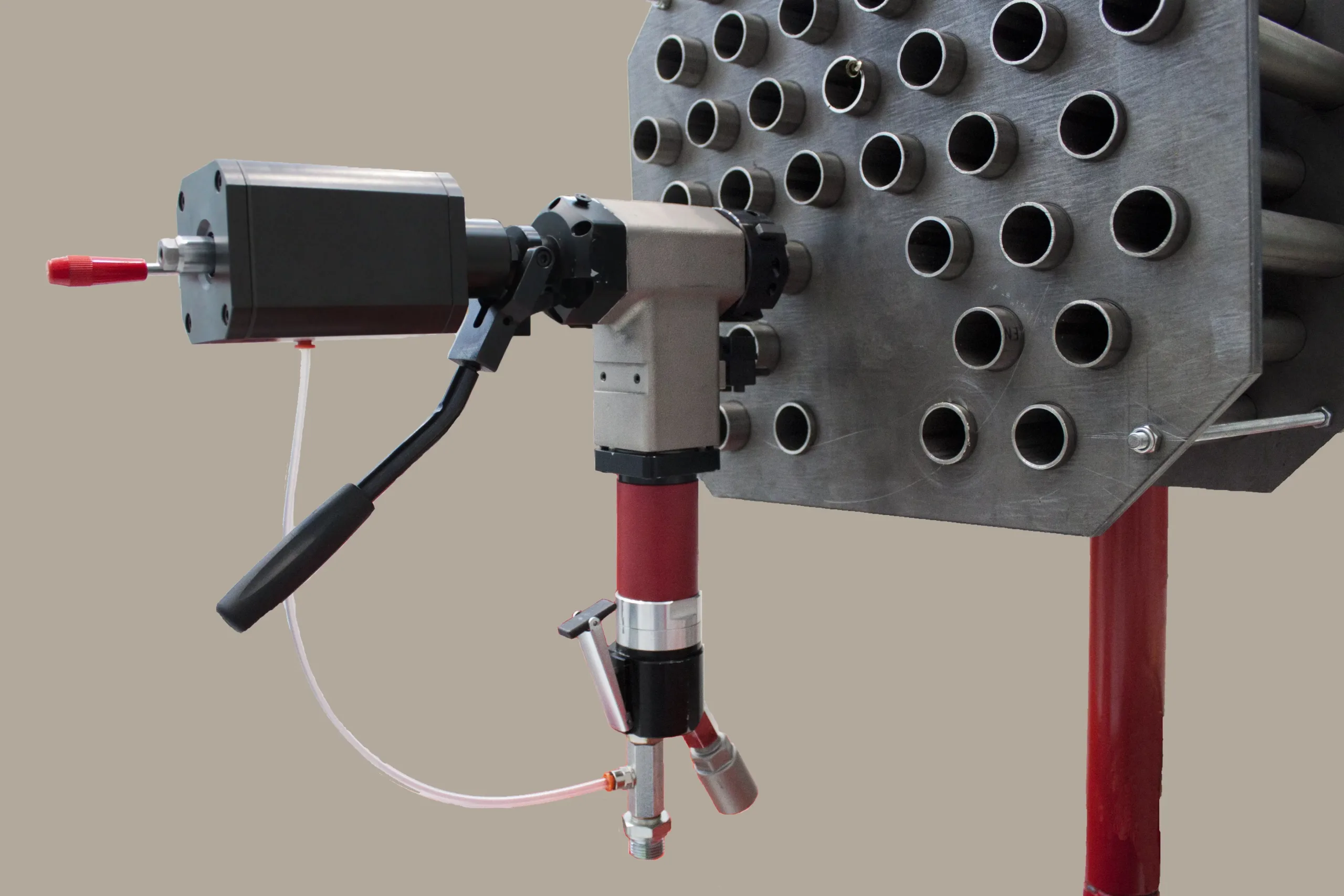

Portable pipe beveling machine MINI K LEVER

Range Øi 20-42 mm (0,78″-1,65″)

The pipe beveling machine Mini K Lever is a pipe beveling machine with reduced dimensions conceived for preparations in series with lever actuated feeding to speed up the working cycle and to help the operator by reducing down to the bare minimum the manual operations.

The pneumatic autolocking device (optional for pneumatic version) can be used on pipe beveling machine Mini K Lever enabling the operator to simplify and speed up the operations during repetitive jobs.

The machine is available in pneumatic version, electric version or battery version.

MACHINE FEATURES

RANGE:

Pipe beveling machine for pipes 20 – 42 mm ø ID (optional up to 12,4 mm).

FUNCTIONS:

Bevel of pipes up to 42 mm ID.

Lever feeding.

MATERIALS:

Carbon steel, stainless steel, duplex, inconel, others.

POWER:

Pneumatic, electric or battery.

CHUCK:

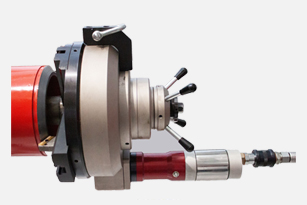

With 4 seats for tools.

Mini K Lever – Pictures

The Mini K Lever pipe beveler has a wide range of uses; it works on carbon steel, alloy steel, ferrous alloys.

Our pipe milling machine is suitable for heat exchangers up to systems for the transport of fluids; It was created to carry out interventions on site, on existing and perhaps deteriorated systems.

Our pipe beveling machine has small dimensions to allow the operator to work in small spaces.

As an option it can be equipped with a shaft for elbows to chamfer T-joints where the clamping space is very limited.

Designed to speed up progress, the main difference compared to our Mini K pipe beveller is the faster use speed for quick and accurate welding preparations. There is also the possibility of using the advancement lever instead of the handwheel.

Contact us if you are interested in the Mini K Lever pipe beveler or would like to receive a free quote.