Description

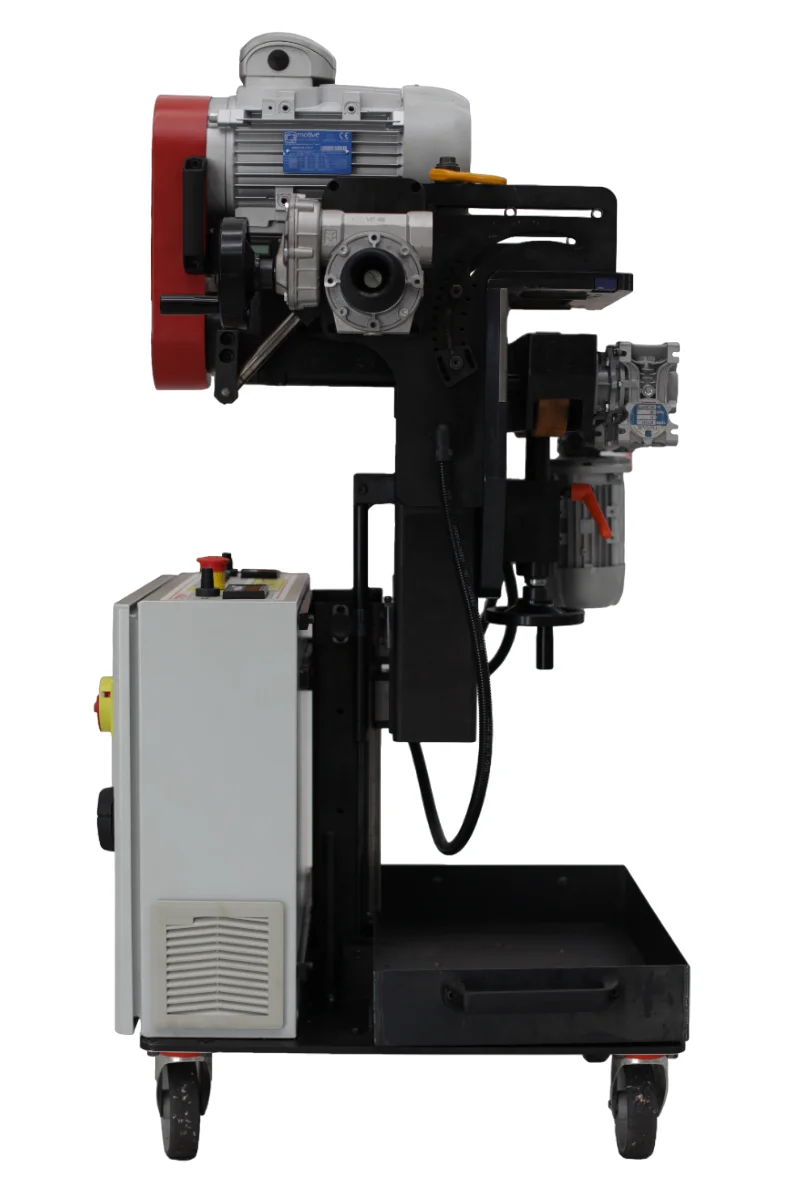

Multifunctional plate beveling machine MULTIEDGE 80

Range w.t. 6-120 mm (1/4” – 4 ¾”)

The plate beveling machine Multiedge 80 is a multifunctional plate beveling machine equipped with an adjustable head that can be easily set in any configuration required for the specific application.

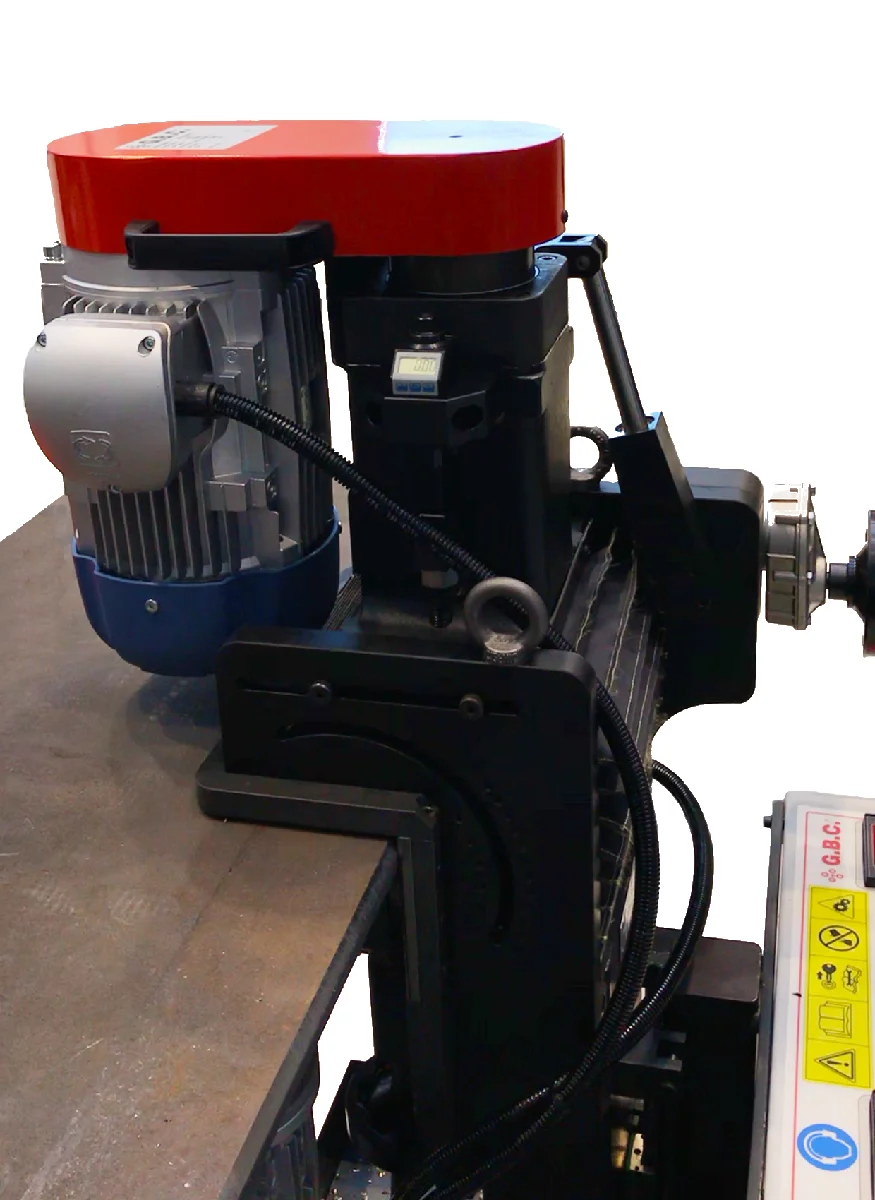

The multifunctional plate beveling machine Multiedge 80 is equipped with two LCD displays for precise adjustments: a display for an easy identification and setup of the angle tilt required for the job; another display for an easy identification and setup of milling head depth.

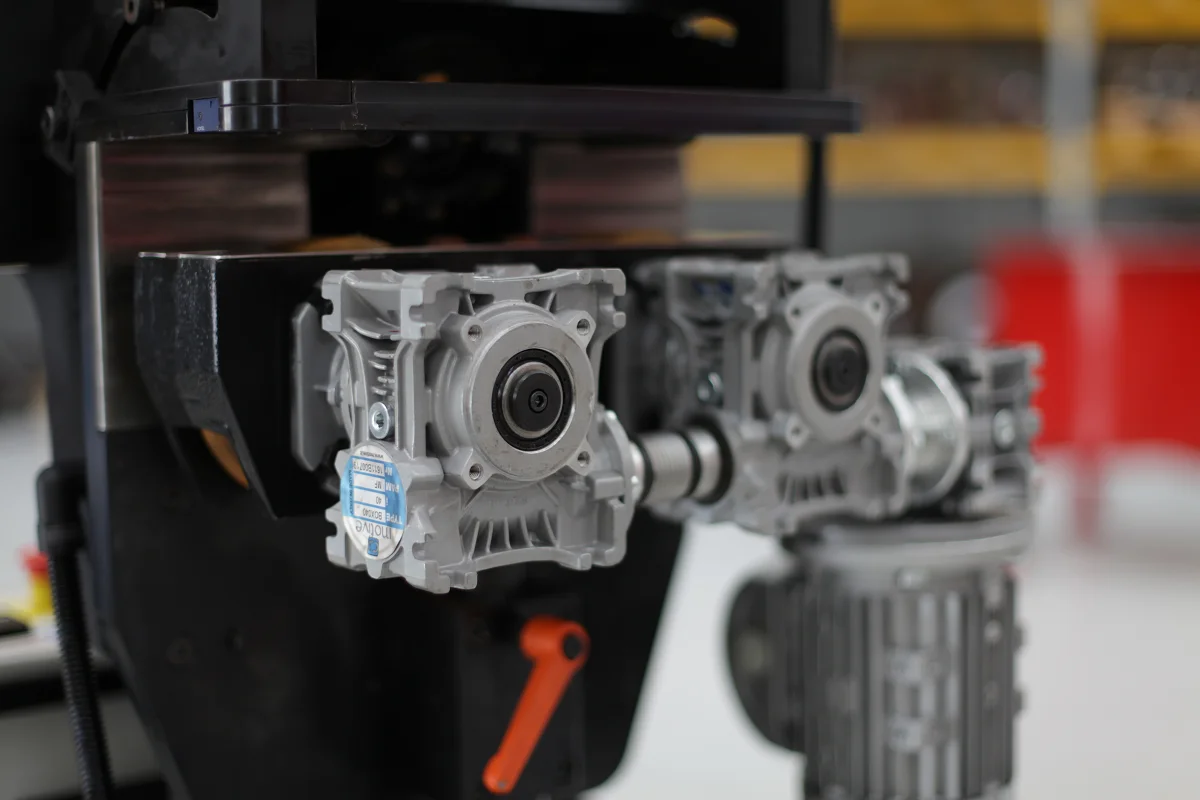

Important characteristic of the Multiedge 80 is the speed regulator fully integrated with the control panel, that enables to adjust the face mill rotation speed from 300 rpm up to 1500 rpm according to the different materials to work.

MACHINE FEATURES

RANGE:

Plates from 6 to 120 mm thickness (1/4” to 2 3/8”).

Maximum diagonal 80 mm.

FUNCTIONS:

Standard bevel.

Facing.

Clad removal.

J Bevel (R6 and R8) from 0° to 30°.

MATERIALS:

Carbon steel, stainless steel, duplex, super duplex, inconel, aluminium, etc.

POWER:

Electric 3 phase 400V 50Hz.

MULTIEDGE 80 – Pictures

MULTIEDGE 80 – Video

The Multiedge 80 Multifunctional plate beveling machine is compact and versatile. With multifaceted functions, such as plating, used from naval to nuclear, it is suitable for large thicknesses, perfect for heavy carpentry.

In compliance with the highest safety standards, it guarantees the protection of the operator thanks to the sheet metal presence detection sensor.

The parameters of our metal plate beveling machine can be set before processing, if the characteristics of the material are known, or varied during work in order to identify the optimal adjustment.

An interesting feature of this sheet metal beveling machine is the integrated trolley, equipped with a chip conveyor device, and a shock-absorbing system to make processing smoother and eliminate any imperfections.

Contact us if you are interested in the Multiedge 80 machine or would like to receive a free quote.