Description

Plate beveling machine COMPACT EDGE

Range w.t. 6-60 mm (1/4” – 2 3⁄8”)

Plate beveling machine Compact EDGE, features a high speed milling head with interchangeable inserts, is a machine with reduced structural dimensions and weightfor a more flexible and dynamic use.

The machine is equipped with a stepless variable head type which allows bevel angles from 15° to 60°, granting a very easy and quick adjustment of the angle of bevel.

The plate beveling machine Compact Edge is equipped with a plate detecting sensor and trolley with a new chips conveyance system. We have also implemented a dual amortization system which allows to overcome eventual imperfections of the wall thickness or eventual variations of the plate, as well as the imperfections of the ground.

MACHINE FEATURES

RANGE:

Plates from 6 to 60 mm thickness (1/4” to 2 3/8”).

FUNCTIONS:

Bevel from 15° to 60°.

MATERIALS:

Carbon steel, stainless steel, duplex, super duplex, inconel, aluminium, etc.

POWER:

Electric 3 phase 400V 50Hz.

CONFIGURATIONS:

Standard and special.

OPTIONAL:

Speed regulator.

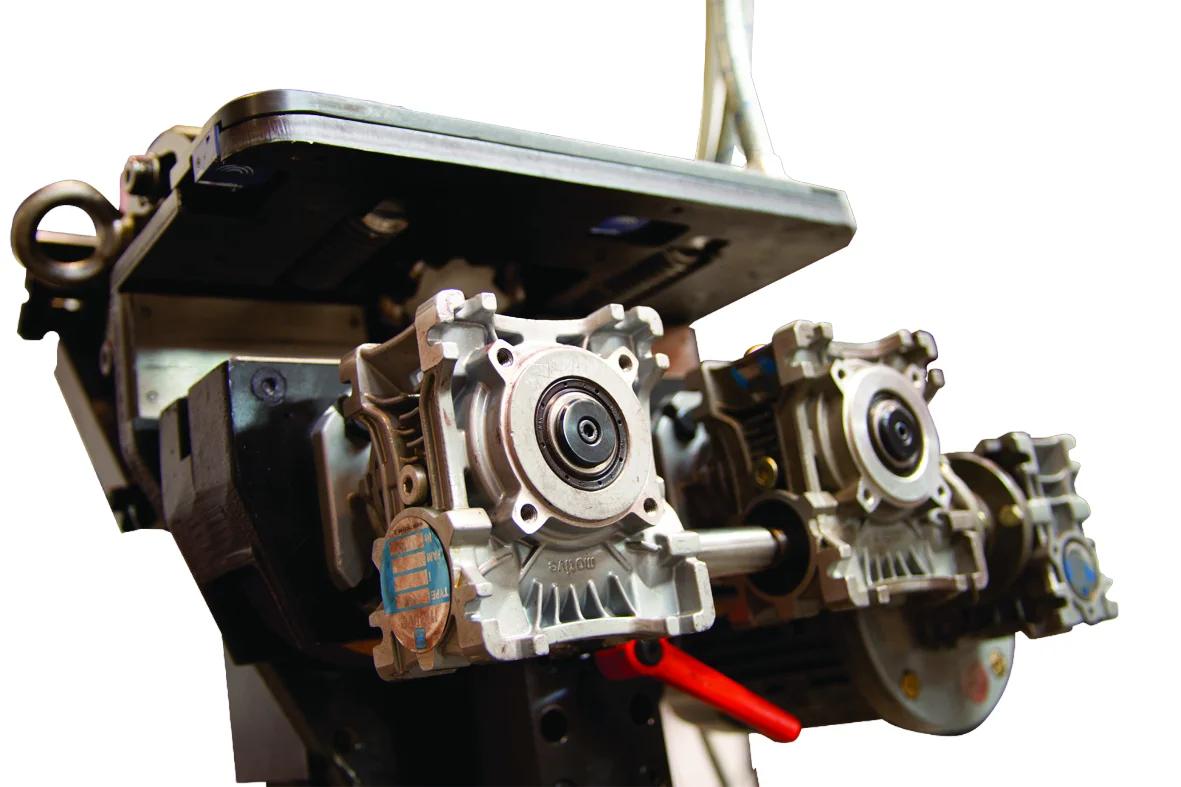

COMPACT EDGE – Pictures

The Compact Edge sheet metal beveller is widely used in workshops and heavy carpentry, for thick metal plates and also in the naval sector. Thanks to its structure, the plate beveling machine can be used in two different configurations:

– “standard” configuration: using the integrated trolley;

– “special” configuration: removing the machine head from the trolley and applying it directly to the edge of the sheet metal.

This plate beveling machine drive unit has been completely renewed, optimizing its dimensions and significantly increasing the quality of motion transmission via a single motor.

The Compact Edge plate beveler series can be equipped with a speed variator. This device, to be considered an optional accessory, can be installed directly on board the beveling machine at the time of purchase or subsequently through a simple connection operation using a multi-connector.

The speed variator allows you to work, with excellent results in terms of quality and productivity, different types of materials, even the most tenacious.

Intuitive and extremely easy to use via the digital display, the new device allows you to vary the speed of the cutter from 300 rpm to 820 rpm. The parameters can be set before processing, if the characteristics of the material are known, or varied during work in order to identify the optimal adjustment.

Contact us if you are interested in the Compact Edge or would like to receive a free quote.