Description

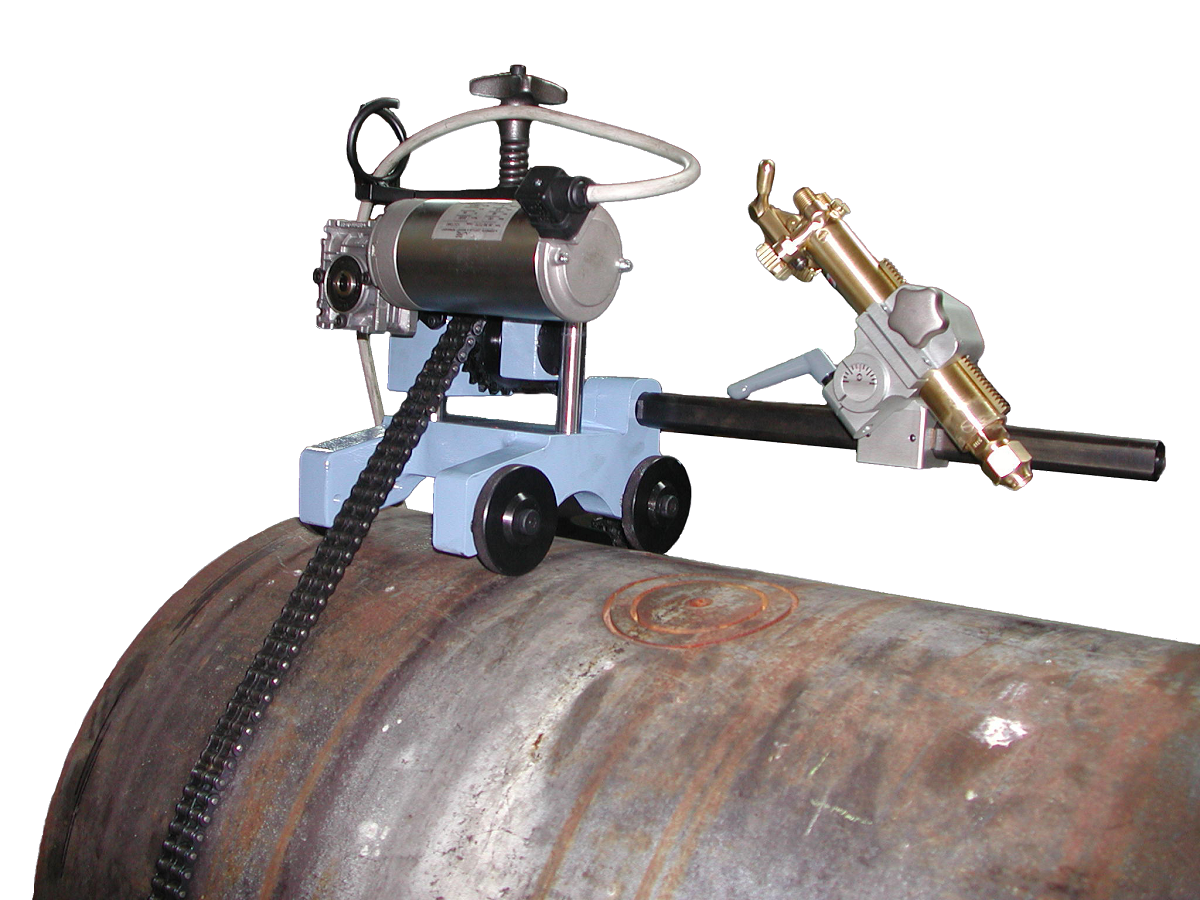

Pipe flame cutting machine GB CUT

Range Øe 101,6 – 2032 mm (4″ – 80″)

The pipe flame cutting machine GB CUT can perform cut & bevel of pipes range from 4” to 80” diameter.

The cutting and/or bevelling is carried out by a cutting torch (acetylene/propane torch upon request) mounted on its specific torch holder. The holder is equipped with scaled junctionin order to allow a perfect positioning of the torch on the cutting start point.

The resulting cut and bevel are therefore straight and precise all around the pipe thanks to a locking system composed of a double link chain and four adjustable wheels with different setting according to the pipe diameter to be machined. The chain is also used to feed the GB CUT rotation around the pipe.

Pipe flame cutting machine GB CUT is available in two versions, manual rotation by hand crank or – alternatively – low tension electric motorized rotation with remote control (the motorization kit can be supplied and mounted on the machine even later on as an optional).

MACHINE FEATURES

WORKING RANGE:

4” – 80″ outer diameter.

WHEELS POSITIONS:

Three Positions (FOR O.D. 4”-16”/16”–32”/32”–80”).

TORCH SET UP AXIS:

Three axis.

POWER:

Pneumatic and electric.

ROTATION:

Manual or low tension motorized kit with remote control.

VOLTAGE:

(for motorized kit version)

220 volt (different voltage upon request)

Voltage in the motor: 24 volt.

OPTIONAL:

Low voltage motorization kit with remote control.

Second torch kit (for cuts/bevels on both edges).

Guide band (recommended over diam. 32”).

GB CUT – Pictures

The low voltage motorization kit is particularly suitable for large diameters, facilitates handling and guarantees a constant rotation speed, making the cutting finish more uniform and precise.

The GB CUT is also equipped with a double crank system made for easy use from any point of the pipe to be machined.

Contact us if you are interested in GB CUT or would like to receive a free quote.